Fully Automatic Continuous Injection Machine

Fully Automatic Continuous Injection Machine

Machine Details

- State-of-the-art technology and world-class machinery imported from Germany.

- Fully Automatic Continuous Injection Machine, the first in Thailand.

- Fully computerized control system.

- High accuracy and precision.

- Steel corrugation system for wall roof panels.

- 5-component chemical mixing system results in authentic FIWall i380 PIR insulated panels with high thermal insulation quality, fire resistance, and smokeless.

- 24-hour chemical storage temperature control to ensure the chemicals are maintained in condition for the best quality of PIR chemical reaction.

- PIR chemical reaction process through temperature-controlled tunnel which is one of the world longest tunnel to result in completed chemical reaction.

- It is fast. It takes only 10 minutes to form the insulation panels.

- Stack cooling for fully cure panel for panel strength and good dimensional stability.

- Automatic wrapping for high quality packing to protect panels through delivery and installation processes.

Important criteria to produce FIWall i380 Authentic PIR insulated panels, Fire Resistance insulated panels by Wall Tech"

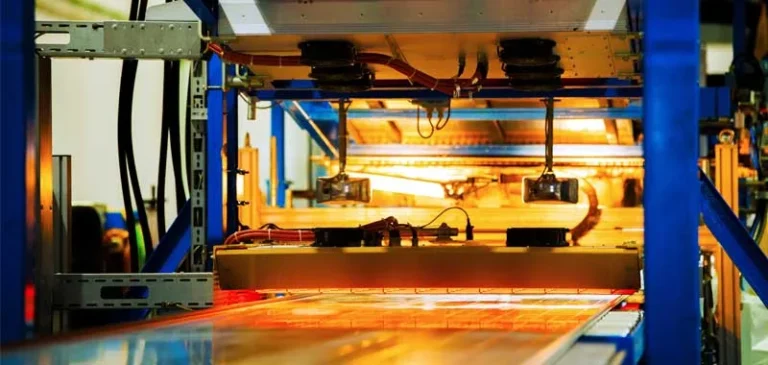

Factor 1: Steel Heating

- Appropriate temperature of steel is required to support the chemical reactions to form the insulated panel.

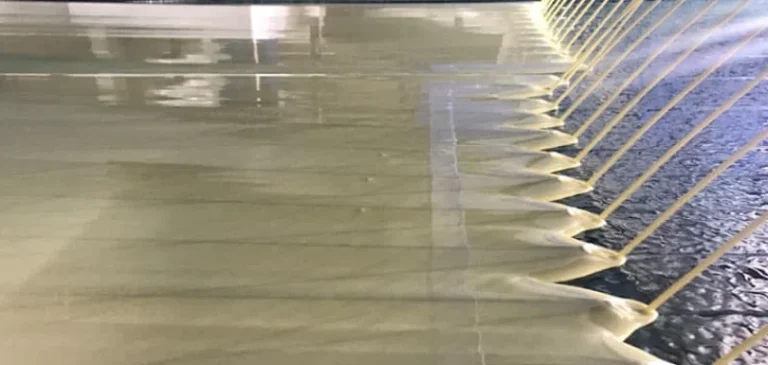

Factor 2: Five-Component Chemicals

- Machines that produce PIR insulation that are available on the market have only 2 components, but Wall Tech chose to use a 5-component system to get authentic FIWall i380 PIR insulation by Wall Tech, premium grade.

- It is a machine that can support mixing up to 5 chemicals because each thickness of FIWall i380 insulation production uses a different chemical formula. Immediately adjusting the chemical ratio to suit the thickness of the sheet. Therefore it is very important. To get authentic FIWall i380 PIR insulation sheets by Wall Tech, good quality in every thickness, whether 50 mm. or 200 mm.

Factor 3: High Precision Metering

- Chemical dosing is managed by high precision metering with accuracy of up to 99.99%. The right and precise chemical ratio is critical for PIR foam quality.

Factor 4: Chemical Storage

- Chemical raw materials, Polyol and Isocyanate, are stored at a temperature of 25 degrees Celsius 24-hours. This storing condition maintains quality of the chemicals to become authentic PIR foam.

Factor 5: Curing

- Curing process through 30-meter long temperature-controlled tunnel, one of the longest in the world, to allow complete PIR chemical reaction.

Factor 6: Make-to-Oder Cutting

- Wall Tech is able to produce customized panel length that suit your requirement. Your building will be completed with desired appearance and good wall strength.

Factor 7: Cooling

- Proper cooling is required to allow fully reacted chemical reaction

- and result in good quality insulated panel with highstrength and dimensional stability for long-term building quality.

Factor 8: Stacking

- Vacuum system lifting to stack up the panels in proper position. This keep the panel in good quality through storing, delivery and installation

Factor 9 Wrapping

- Wrapping and packing the stacked panels for well protection the panel from scratch and environment. Keep panel quality good until installation completion.

Wall Tech is ready to serve you with our expertise more than 30 years

of experience in cold room and insulated panel industry. Consultancy and Inquiry here.

of experience in cold room and insulated panel industry. Consultancy and Inquiry here.