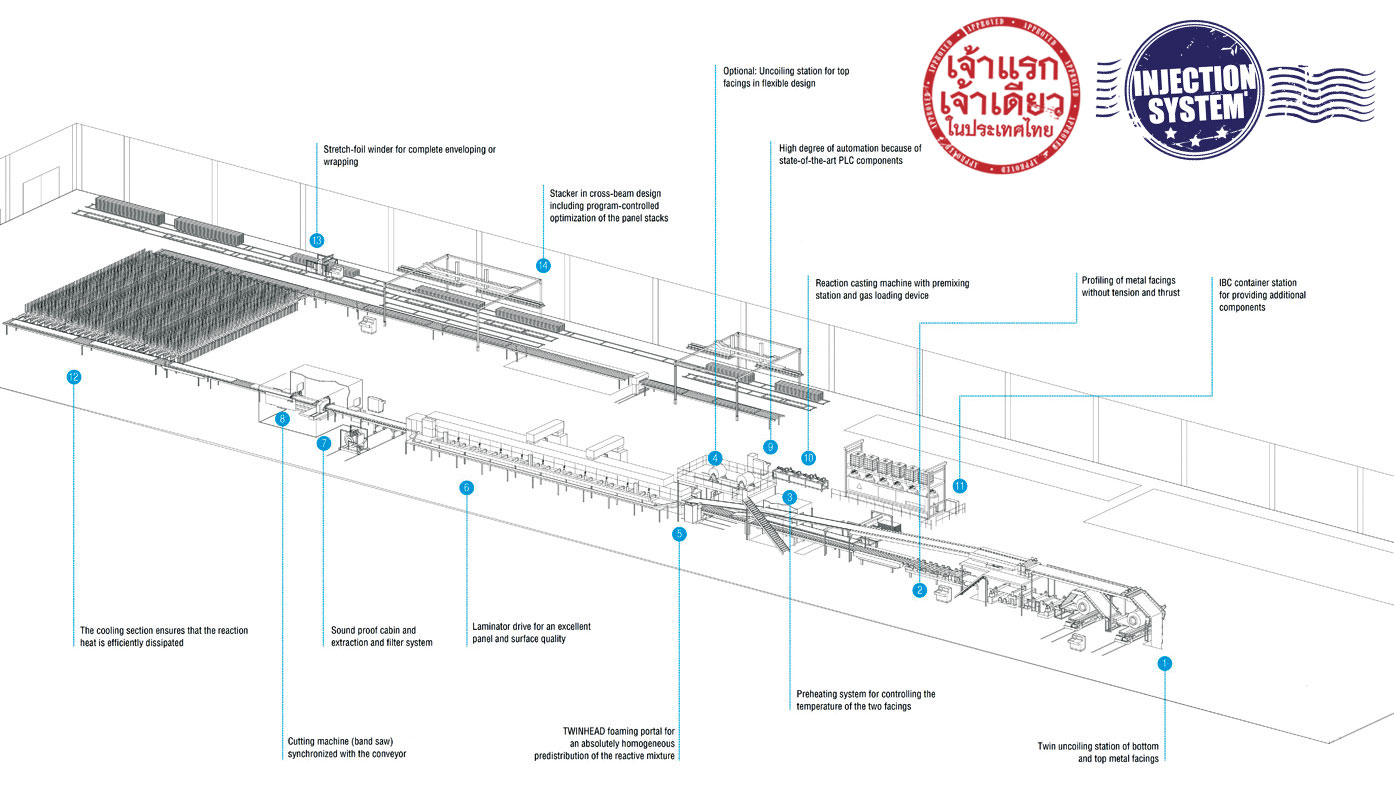

Fully Automatic Continuous Injection Machine

Properties of Fully Automatic Continuous Injection Machine

- The machine has the quality and the most modern from Germany.

- Wall Tech uses Fully Automatic Continuous Injection Machine which is the first and only company in Thailand.

- Production controls with full computer systems every step.

- High precision and accuracy which can ensure that every sandwich panel has the quality.

- Profiling system of steel sheet for the insulation walls and roofs.

- 5-component chemical system making the real PIR by Wall Tech, which has high quality, fireproof, and smokeless.

- For material storage, the premium grade chemicals are kept at 25 °C at all times in order to always get fresh chemicals.

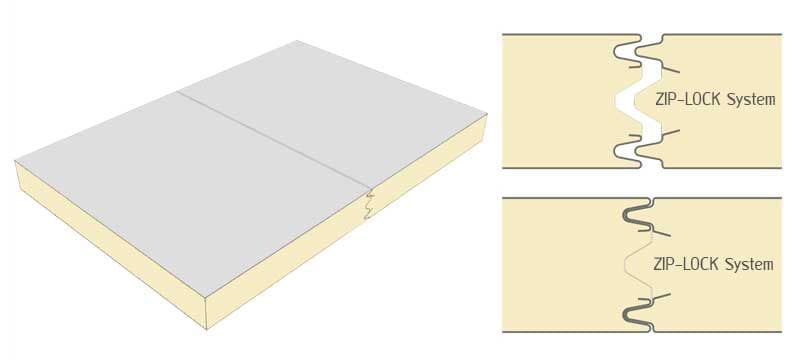

- The connection system design of ZIP-Lock insulation is not only powerful locking but also help to resist fire which can protect life and property.

- Insulation forming just only 10 minutes.

- Having Stack Cooling causes a chemical reaction completely.

- Wrapping system can store and move insulation panels quickly increasing performance.

The key parameters that cause "FIWall i370, a real PIR by Wall Tech", Fireproof and Smokeless

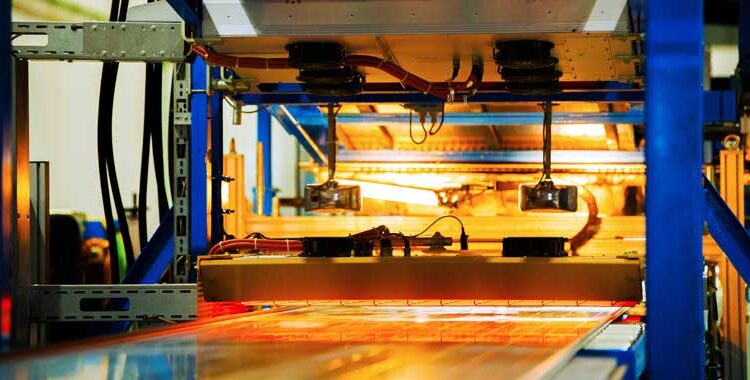

Parameter 1 : Heating

- The first parameter is heating a steel sheet at the right temperature to support chemical reactions during the formation of the insulation completely.

Parameter 2 : 5-component Chemical System

A machine which produces PIR insulation (not real PIR) available in the market is 2-component Chemical System, but Wall Tech chooses 5-component Chemical System to obtain the real PIR insulation “FIWall i370”, Premium grade and the machine can support 5-component Chemical System.

Because the production of FIWall i370 each thickness uses a different chemical formula. Therefore, the ratio adjustment of a chemical to suit the thickness immediately is an important point in order to get FIWall i370, a real PIR by Wall Tech, Premium grade in every thickness no matter 50 mm. or 200 mm.

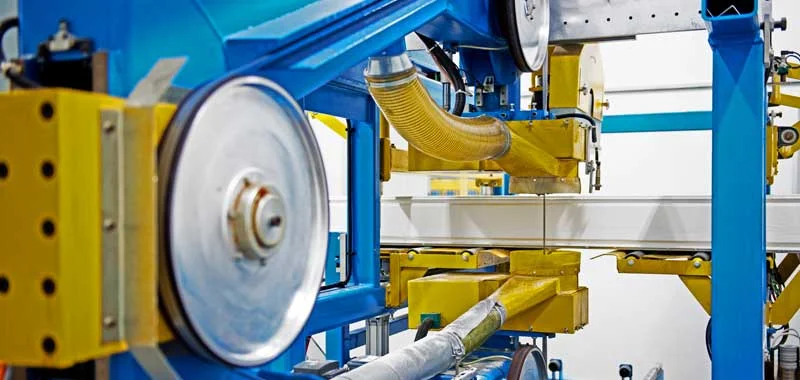

Parameter 3 : High Precision

- When there is a 5-component Chemical System, it must have a controller or Metering system, which is precise up to 99.99%. Wall Tech uses technology from Germany to control the ratio of the 5 components in the production of FIWall i370, in order to obtain the accurate proportions throughout the production.

Parameter 4 : Material storage

- The main chemical of FIWall i370 production, a real PIR by Wall Tech, is a Polyol and Isocyanate. Both must be kept at 25 °C at all times to stay fresh and prevent bubbles.

Parameter 5 : Curing time

- The FIWall i370 production, a real PIR by Wall Tech, needs to be controlled at the appropriate temperature throughout the tunnel. The tunnel is 30-meter length double belts considered to be one of the longest tunnels in the world. This parameter is to support the completely PIR reaction in order to reach the real PIR, premium quality.

Parameter 6 : Made-to-Order Cutting

- Made-to-Order Cutting apart from working controlled by computer and robot is also able to determine the length of the insulation complied with the requirement of using. Some warehouses or industries are 10 m heights which Wall Tech can supply the insulation panels at this height by seamless having both strength and energy saving.

Parameter 7 : Cooling Conveyer

Even the chemical reaction is running completely, the reaction needs to be stopped by “Cooling Conveyer”, which is another important step. This cooling conveyer allows the individual panel cooling to cool down the temperature as Wall Tech understands the nature of the chemicals. The FIWall i370 will shrink if its temperature is still high because the PIR reaction is not completely stopped.

Parameter 8 : Stacking Process

- In this step, there is continuing using a robot to array the product. The robot will lift each panel of FIWall i370 up by using the vacuum system resulting in no scratch and blame.

Parameter 9 : Wrapping Process

- Wrapping process is the process of wrapping FIWall i370, the real PIR by Wall Tech, by automatic machinery for transportation.

Contact us

Thank you for your visiting our website and your interest in our products. Your feedback is highly appreciated and will help us to improve our products and services. We are looking forward to your feedback.